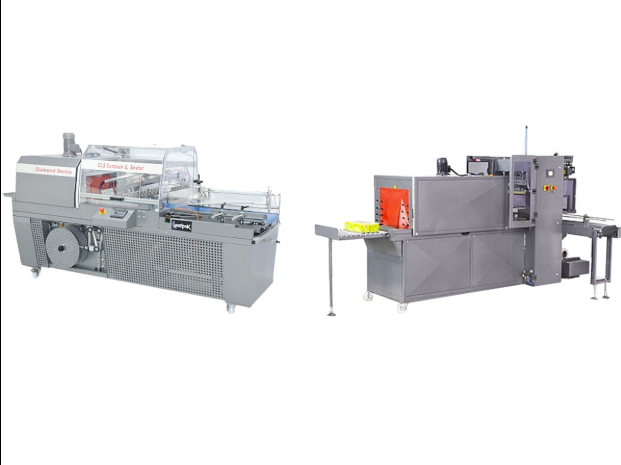

A well-maintained auto shrink wrap machine is essential for efficient packaging operations. These machines streamline the wrapping process, ensuring products are securely sealed and ready for shipment. However, even high-quality machines can encounter issues that affect performance, productivity, and product safety. Understanding common problems and their solutions helps operators maintain smooth operations, minimize downtime, and extend the lifespan of the equipment.

Common Problem 1: Inconsistent Sealing

One of the most frequent issues in an auto shrink wrap machine is inconsistent sealing. This can be caused by incorrect temperature settings, worn sealing wires, or improper film tension. To resolve this, check the machine’s temperature controls and adjust them according to the manufacturer’s recommendations. Inspect the sealing wires for wear or damage and replace them if necessary. Ensuring the film is correctly loaded and tensioned also prevents uneven seals and improves packaging quality.

Common Problem 2: Wrinkling or Tearing of Film

Wrinkled or torn film is another challenge that operators may encounter. This often occurs due to improper film handling, incorrect heat settings, or a misaligned conveyor. To troubleshoot, verify that the film is feeding smoothly and evenly. Adjust the heat and shrink tunnel settings to ensure the film conforms to the product without excessive tension. Regular inspection of the conveyor and guides helps prevent misalignment and reduces the likelihood of film damage during operation.

Common Problem 3: Machine Jamming or Stalling

Jamming or stalling can halt production and reduce efficiency. Causes include debris in the machine, worn rollers, or electrical malfunctions. Routine cleaning and lubrication of moving parts are essential for preventing jams. Inspect rollers, belts, and gears for wear and replace them as needed. Electrical checks should be performed periodically to ensure connections are secure and components are functioning correctly. By addressing these issues proactively, operators can maintain a continuous workflow and reduce downtime.

Common Problem 4: Uneven Shrinking

Uneven shrinking can result in improperly wrapped products, affecting both aesthetics and protection. This problem often stems from incorrect tunnel temperature or airflow issues. Ensure that the shrink tunnel is operating at the recommended temperature and that fans or blowers are functioning correctly to provide even heat distribution. Properly spaced products and correct film selection also contribute to uniform shrinking. Following manufacturer guidelines ensures optimal results and minimizes packaging defects.

Common Problem 5: Excessive Noise or Vibration

Excessive noise or vibration is not only disruptive but can indicate mechanical problems. Worn bearings, loose components, or misaligned parts often cause these symptoms in an auto shrink wrap machine. Regular maintenance, including tightening loose bolts, lubricating bearings, and checking alignment, reduces operational noise and prevents further damage. A quieter, well-aligned machine improves operator comfort and prolongs equipment life.

Preventive Maintenance Tips

Preventive maintenance is key to minimizing issues and ensuring reliable performance. Schedule routine inspections, clean the machine regularly, and replace worn parts promptly. Keep an organized maintenance log to track repairs and servicing. Proper operator training also reduces user errors and enhances efficiency. By adopting a preventive approach, businesses can avoid unexpected breakdowns, improve product quality, and maintain consistent throughput in their packaging lines.

Conclusion

Understanding and troubleshooting common issues in your auto shrink wrap machine ensures smooth operations, reduces downtime, and enhances product presentation. Regular inspections, proper maintenance, and adherence to manufacturer guidelines are essential for consistent performance and longevity. Addressing problems such as inconsistent sealing, wrinkled film, machine jamming, uneven shrinking, and excessive noise ensures efficient and reliable packaging processes. For businesses looking to upgrade or expand their packaging capabilities, investing in high-quality machines for packaging guarantees durability, efficiency, and professional results for every operation.